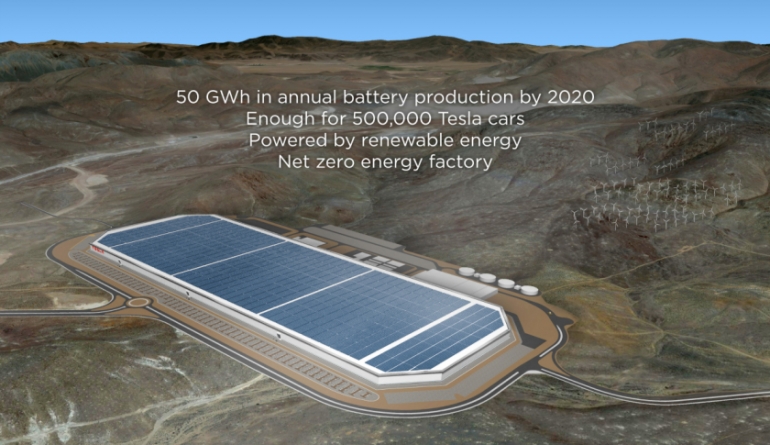

The $5 billion facility, projected to be completed in 2017, is intended to produce 500,000 lithium ion batteries annually. But advances in battery technology could threaten the gigafactory’s viability.

A disruptive shadow looms over Tesla Motors’ giant Nevada “gigafactory”—the threat of rapidly advancing battery technology. While plenty of hurdles face new battery tech, the emergence of a viable and significantly better battery in the next five years could turn Tesla’s $5 billion facility for mass producing lithium-ion batteries into a giga-albatross.

In January, Fuji Pigment Co. Ltd. (not affiliated with Fujifilm) announced that it had made a significant breakthrough in aluminum-air battery technology. Aluminium-air batteries have a theoretical capacity more than 40 times greater than the lithium-ion cells Tesla will soon mass-produce, and Fuji Pigment has stated it will commercialize its innovation by the end of 2015. This means that the gigafactory’s products could already be outclassed before its target 2016 opening—and long before the estimated 7-10 years of full production it could take to recoup the factory’s costs.

Battery innovation takes place within a rigid structure: every battery has two ‘sides,’ the cathode and anode, which react through an electrolyte medium to produce power. An aluminum-air battery generates electricity from the reaction of oxygen and aluminum, using water as an electrolyte. A standard aluminium-air reaction consumes the aluminum anode, which must be physically replaced rather than electrically recharged. But Fuji Pigment claims that, by adding strategically placed layers of ceramic and carbon, it has managed to suppress corrosion and reaction byproducts, creating an aluminium-air battery that can be recharged multiple times by simply adding water.